About us

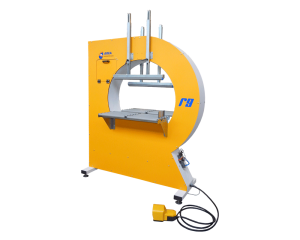

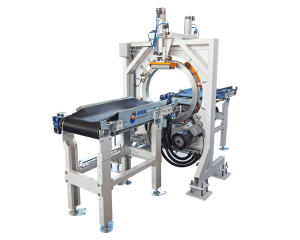

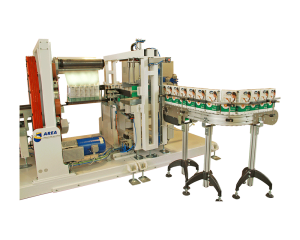

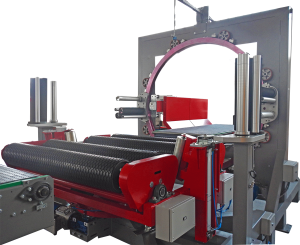

AREA designs and manufactures complete machines and lines for wrapping and packaging products that develop lengthwise, capable of fulfilling the functions requested by the customer and integrating with other systems and production lines.

In a very short time, thanks to great commitment and determined conviction, AREA has acquired a leading position in the production of horizontal axis stretch film wrapping machines. AREA’s activity is based on the study of the movement of goods within the Customer’s production plant, analyzing the needs, feasibility and correctness of the flows, taking into account the interface with any other systems and the conformity of the project.

Leader in the production of horizontal axis stretch film wrapping machines.

Thanks to the experience gained over the years in the field of horizontal packaging, AREA is able to offer customized solutions designed and built to satisfy even the most demanding customer’s requests.

AREA’s activity is not limited to the production of the machines but continues up to commissioning and concludes with the verification of the correctness of the flows.

The professionalism gained in recent years, with machines installed in more than 25 countries around the world, allows AREA to address the national and global market by offering innovative and customized solutions, also obtained thanks to the attention and use of new design experiments, which guarantee the excellent construction quality achieved.

Company history

I am Alessandro Cattaneo, CEO of Area Srl. In December 1998, after long experience in the packaging machinery sector, I realized that the market had specific needs in the packaging of products that develop lengthwise.

I thought that this problem could be solved by developing extremely “customized” machine models which had the aim, in addition to the packaging of the products, also of great savings in electricity and consumables.

AREA was founded in 1999, on the initiative of Alessandro Cattaneo who, after many years of work and experience in the world of packaging, established a new business unit dedicated to the construction of horizontal axis wrapping machines. AREA is aimed above all at those product sectors that need to package products that extend lengthwise.

The company’s innovative imprinting has as its primary aim that of guiding customers in the development of new perspectives through the implementation of cutting-edge automated systems to always propose the most suitable solution to respond to the various needs for optimizing the packaging process .

Thanks to the experience acquired in recent years, AREA holds an enviable position in the customized packaging sector, both in terms of completeness of the range and technological cutting edge of its products.

AREA offers packaging machines and systems which, in addition to guaranteeing maximum safety, optimize time and resources in the packaging and management of goods process, improving the efficiency of the production and logistics process.

Mission

AREA’s mission is to respond to precise customer needs. For this reason it dedicates particular interest to the study of times and methods, which are fundamental today to make companies increasingly competitive, and invests many of its resources in the training and growth of its staff.

AREA’s objective is to create packaging of the highest quality and safety level for any need, to do so in close collaboration with the customer and to establish a relationship of partnership and trust with him.

AREA is constantly looking for new solutions that can guarantee greater income and quality

with full respect for man and the environment. The optimization of production processes in order to improve the reduction of costs and environmental impact. Sustainability is a determining element in AREA’s production philosophy.

Solving problems and saving money, this is the mission of Area Srl.

- Electricity: savings of up to 90% compared to other systems (e.g. heat shrink)

- Consumables: savings of up to 50% also considering the elimination of protective corners (e.g. strap)

Why choose Area

AREA has developed a different way to assemble, contain and protect single products or multiple loads without using what tradition has always proposed: strap and heat shrink!

The use of horizontal axis stretch film wrapping machines allows you to:

- SAVE up to 50% in terms of consumables (plastic film) and eliminate the use of cardboard corners (for strapping)

- REDUCE electricity costs by 90% (stretch film = cold processing, shrink film = hot processing)

- ELIMINATE format changes – continuous processing of products with different widths

- INCREASE production capacity

- COMPLETELY AUTOMATE the packaging phase

- IMPROVE the aesthetic appearance of the finished product

- USE only completely recyclable material (polyethylene)

- MANAGE product handling and storage with better results

The continuous evolution of AREA products today allows various solutions:

- wrapping products only with stretch film

- protection of the product, before wrapping with stretch film, with air bubble film or with expanded polyethylene film

- package head and tail coverage

- insertion of wooden or polystyrene strips under the package, thus excluding the use of the pallet

- continuous film cutting system, avoiding stopping the product during the packaging phase and considerably increasing production capacity

- excellent winding results even with short products

Area and the Environment

AREA has developed innovative technologies always taking into account environmental sustainability. Today AREA can affirm that the energy saving objective has been achieved beyond the most optimistic forecasts.

Packaging products with the systems designed by AREA drastically reduces the amount of material used and consequently the amount of material to transport. Furthermore, the amount of electrical energy required is lower than that used for other packaging systems.

AREA srl has dedicated a large part of its investments to research in recent years with the aim of reducing the impact on the environment on the one hand and the incidence of costs on the other.

Precisely for this reason AREA has:

- developed, together with the manufacturers of consumables, machines that can use stretch film of increasingly thinner thickness

- reduced the use of electricity for the operation of the machines

- maintenance costs have been reduced to minimum values